In recent years, glulam (glued laminated timber) has been predicted by experts to be the high-tech building material of the future. As steel and concrete constructions tend to lag behind due to increasing environmental costs, wood architecture – in all shapes and sizes – is asserting itself in a class of its own.

Tracing back to the dawn of human civilization, fire has always been an indispensable element for survival. However, to keep the flame burning, wood proves to be even more crucial. This highlights the enduring bond between humanity and wood, a material that has played a pivotal role in various aspects of life throughout history, particularly in architecture and construction.

From the rudimentary use of roughly hewn natural wood in early structures, humans have gradually pioneered advanced wood processing and manufacturing solutions to enhance the material’s durability and overall design. Among these innovations, Glulam (Glued Laminated Timber) stands out with its diverse colors, high durability, moisture resistance, and the ability to create large, uniquely shaped components.

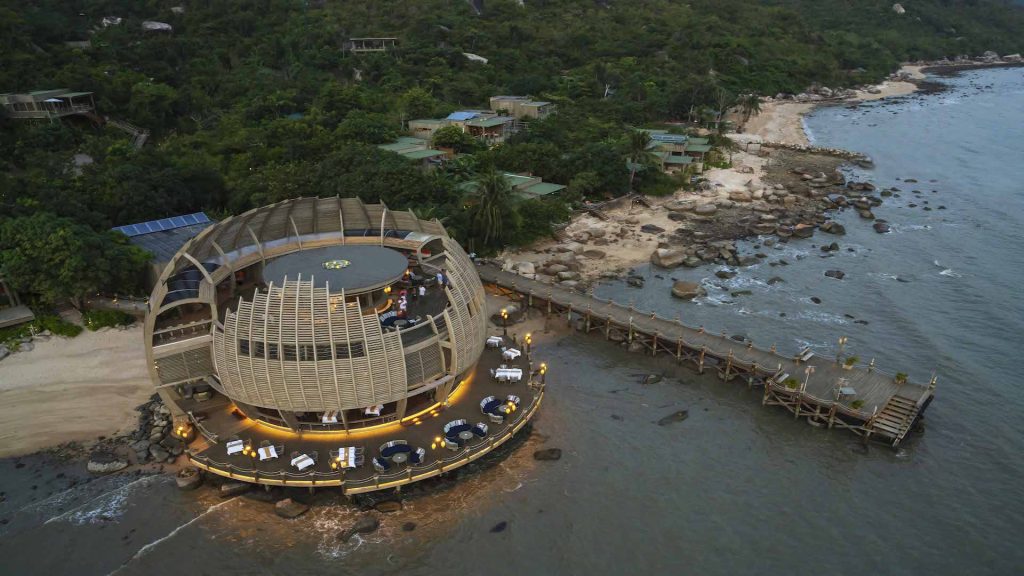

The Sen Restaurant at An Lam Retreats Ninh Van Bay exemplifies the superiority of glulam. (Image source: TranDuc Homes)

The Sen Restaurant at An Lam Retreats Ninh Van Bay exemplifies the superiority of glulam. (Image source: TranDuc Homes)

Globally, the use of wood as a substitute for conventional materials like steel and concrete has become commonplace. However, in Vietnam, this trend is relatively nascent and has sparked some apprehension. The primary concern stems from worries about wood’s durability and stability in Vietnam’s climate, coupled with the higher construction costs compared to concrete and steel. Additionally, there are concerns about the lack of control over wood material sources and potential adverse environmental impacts. Glulam emerges as a precise solution to address these issues.

Glulam, with its superior properties, is ideal for outdoor applications such as resorts, restaurants, and hotels. The image depicts the Sofia Cafe project using glulam designed and constructed by TranDuc Homes.

Using wood with a 10-25 year lifecycle, sourced from state-regulated areas, Glulam has swiftly become a “green star” in environmentally friendly construction projects. TranDuc Homes, the entity behind notable projects like the Sen Restaurant at An Lam Retreats Ninh Van Bay in Khanh Hoa and Phu Cuong Cafe in Kien Giang, states that the glulam used in their projects is derived from trees nurtured in nurseries for 5-7 years before being used to replace mature trees ready for harvesting. This minimizes illegal deforestation while fostering natural ecosystems and protecting the environment. Notably, this entire process is rigorously audited by governments of developed nations such as the UK, USA, Canada, and Australia before being imported into Vietnam for further processing.

Specifically, glulam employs advanced lamination techniques and industrial adhesives, resulting in high durability and moisture resistance, significantly reducing warping, twisting, and cracking. According to experts, this material is classified as a reusable resource with fire-resistant properties. Unlike steel, glulam forms an insulating layer when exposed to high temperatures, protecting the internal structure and ensuring the building remains stable under heavy loads, enhancing safety.

One of the advantages that makes glulam a preferred material for designers and builders is its bending capability, 80% better than natural wood, and the ability to increase wood length through finger jointing. With greater deformation resistance than concrete, glulam can withstand higher stress levels while being lightweight and possessing comparable structural strength, facilitating assembly, maintenance, and dismantling.

The flexibility of glulam expands the scope of wood applications in construction, stimulating creativity and enhancing design aesthetics. (Image: L’alya Ninh Van Bay Resort designed and constructed by TranDuc Homes)

Glulam is also treated with the world’s most advanced methods to enhance stability and weather resistance, minimizing emissions during processing as it consumes only 1/6 of the energy required for steel production.

The rustic yet sophisticated appeal of glulam at the Ben Tre house project, designed and constructed by TranDuc Homes.

Notably, compared to concrete and steel, glulam projects can be completed in a much shorter timeframe as all materials are prefabricated and dry. On average, glulam can be installed three times faster than cast-in-place concrete.

With its outstanding advantages that benefit not only the structure but also people and the natural environment, glulam is undoubtedly a material of the future. “In the trend of returning to the core values of nature, glulam projects will fulfill the desire to immerse in a unique, rustic yet modern and high-end living space. That is also our long-term goal,” a representative from TranDuc Homes affirmed the important role of glulam.

Contact us for more information

0988 897 997

With over 20 years of experience, TranDuc Homes proudly stands as the leading provider of comprehensive solutions for the Architecture and Construction sectors in Southeast Asia. TranDuc Homes is aiming for a future where our solutions not only lead in quality but also pioneer the development of green construction, sustainable living, and environmental protection.

HCM Office:

Unit 901, The Waterfront Saigon, 1-1A-2 Ton Duc Thang, Sai Gon Ward, Ho Chi Minh City, Vietnam.

Factory:

69/13 Binh Chuan 42 Street, Binh Phuoc A Quarter, An Phu Ward, Ho Chi Minh City, Vietnam.

E-Mail: [email protected]

Phone: 0988 897 997