In the rapidly evolving landscape of architecture and construction, where sustainability is paramount, Cross-Laminated Timber (CLT) has emerged as a compelling alternative to traditional concrete and steel. Architects, engineers, and developers today prioritize not only aesthetics and structural integrity but also reduced emissions and optimized timelines.

TranDuc proudly introduces CLT “Made in Vietnam – Global Quality,” partnering with you from design conception to the realization of green building projects

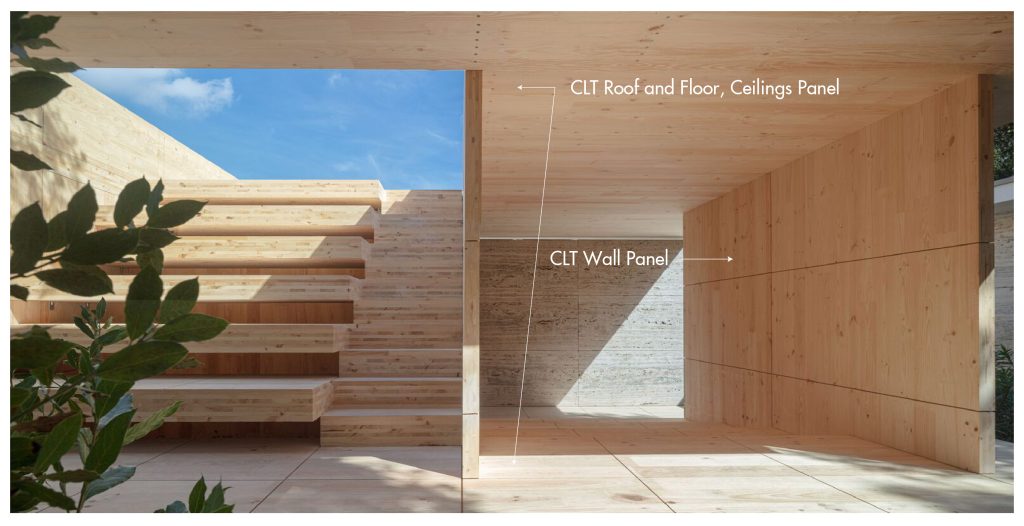

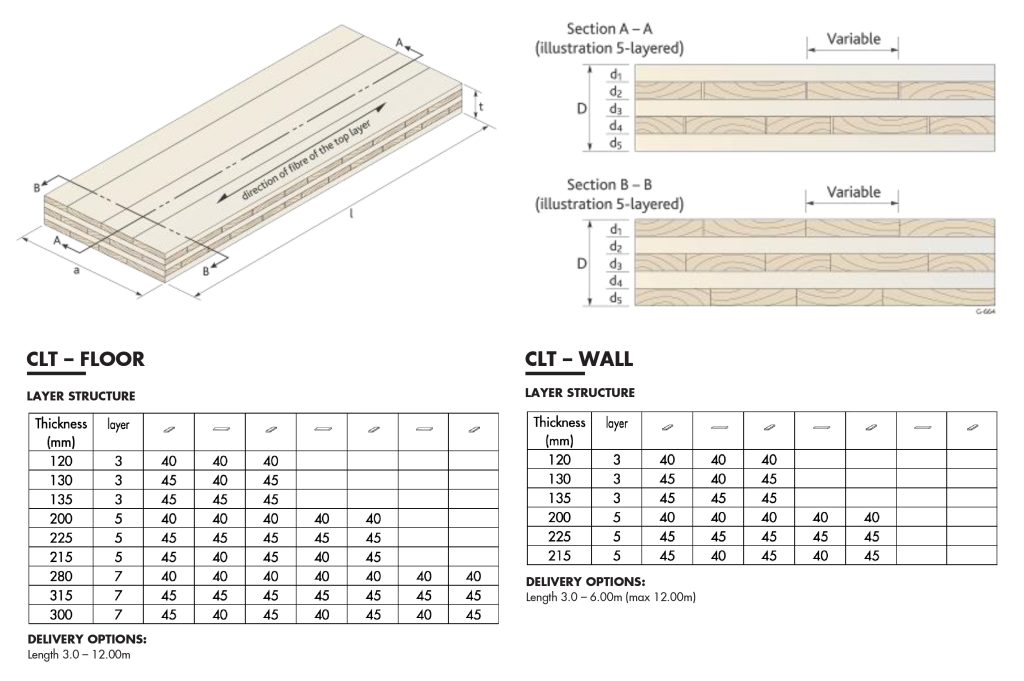

CLT is an engineered wood panel made from multiple layers of kiln-dried lumber, with each layer oriented at a 90-degree angle to the adjacent layers and bonded with structural adhesives. This cross-lamination creates a two-way structural panel with exceptional stiffness and stability.

Compared to concrete, CLT is approximately 20% of the equivalent weight, resulting in reduced foundation loads and transportation costs. The cross-layered structure minimizes warping and shrinkage while offering the natural warmth and beauty of wood, seamlessly integrating with various modern architectural styles.

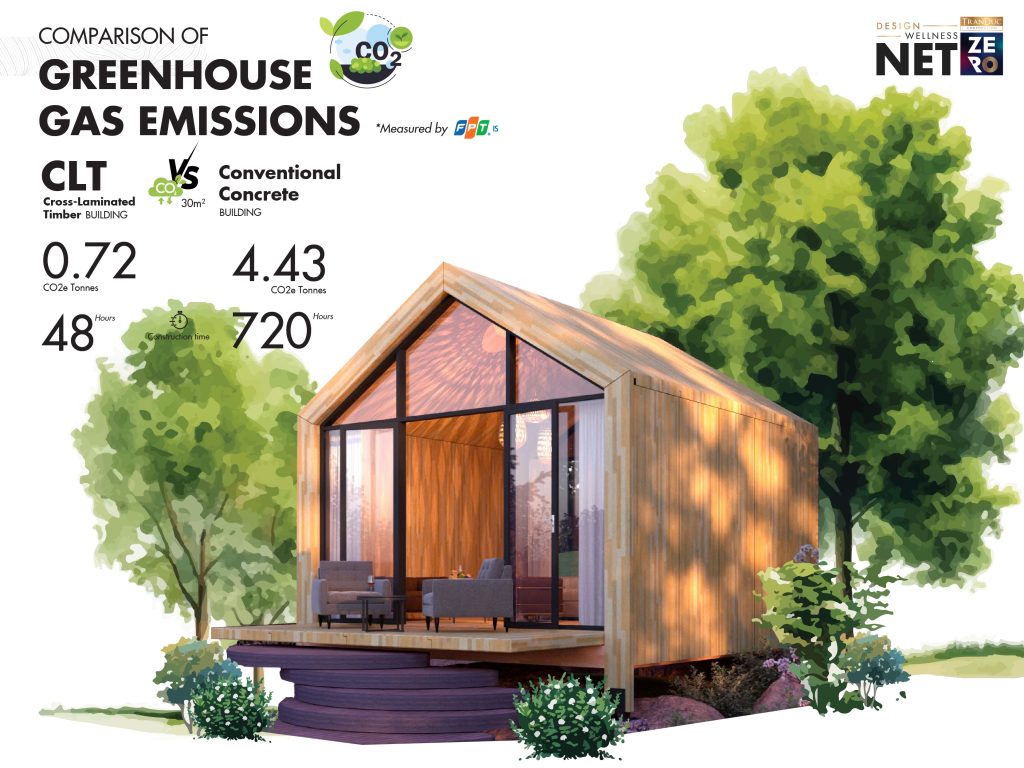

CLT enables developers and contractors to significantly shorten construction schedules due to off-site prefabrication and rapid on-site assembly. Its lightweight nature reduces foundation requirements, leading to cost savings in structural elements and logistics. Furthermore, CLT helps reduce CO₂ emissions by 20–25% compared to traditional concrete solutions, contributing to achieving green building certifications like LEED or EDGE and meeting increasingly stringent ESG criteria.

With over two decades of experience in high-end wood and furniture manufacturing, we guarantee exceptional quality and reliability.

We apply the most advanced CLT production technologies and processes through our European R&D partnerships

From luxury residential projects to office buildings and hotels, TranDuc meets all requirements and standards for implementation across all elements: from primary structural components and facade systems to decorative interior features

From raw material selection to final inspection, every step is rigorously controlled, providing absolute peace of mind for architects, engineers, and developers.

With over two decades of experience in high-end wood and furniture manufacturing, we guarantee exceptional quality and reliability.

CLT is more than just a material – it’s a green building solution empowering architects, engineers, and developers to optimize timelines, save costs, and achieve sustainability goals. With Vietnam’s first Net Zero factory boasting a 12,000 m³/year capacity, TranDuc is committed to being your trusted partner from initial design concepts to completed green buildings.

With over 20 years of experience, TranDuc Homes proudly stands as the leading provider of comprehensive solutions for the Architecture and Construction sectors in Southeast Asia. TranDuc Homes is aiming for a future where our solutions not only lead in quality but also pioneer the development of green construction, sustainable living, and environmental protection.

HCM Office:

Unit 901, The Waterfront Saigon, 1-1A-2 Ton Duc Thang, Sai Gon Ward, Ho Chi Minh City, Vietnam.

Factory:

69/13 Binh Chuan 42 Street, Binh Phuoc A Quarter, An Phu Ward, Ho Chi Minh City, Vietnam.

E-Mail: [email protected]

Phone: 0988 897 997